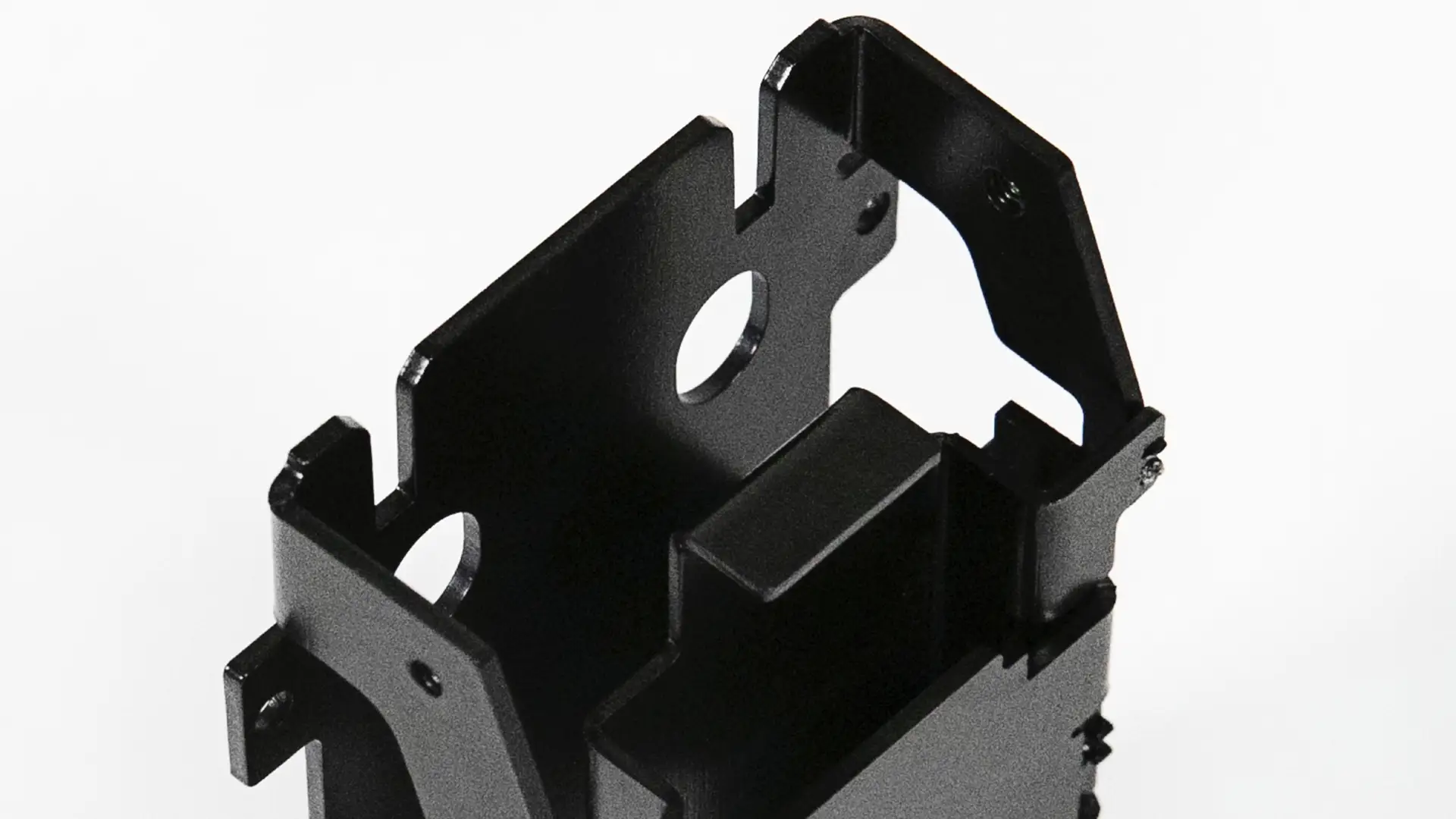

What is Industrial Design? Focused on Metal Sheet Components

Industrial design combines creativity and technology to develop useful, attractive, and functional products. It’s not just about appearance; it’s about understanding and meeting user needs, ensuring that products are practical, safe, and durable. At JOM METAL PARTS MANUFACTURING, S.L., we work closely with our clients to bring their ideas from the initial concept to production. Here’s how we support them at each stage of the industrial design process.

1. Understanding User Needs

The first step in industrial design is to analyze who will use the product and what they expect from it. This involves knowing the context of use and the product’s functional requirements. And at JOM, how do we help our clients in this stage? By requesting the assembly and usage requirements for each component to guide and offer the best solutions for their specific needs.

2. Conceptualization and Creativity

Creativity is essential to generate innovative and effective solutions. During the conceptualization phase, designers visualize the final product and explore different ideas that combine aesthetics and functionality. How do we collaborate at JOM? With our experience across a wide range of sectors, we bring our knowledge in sheet metal and technology, advising on new techniques and processes to optimize the final design.

3. Material Selection and Sustainability

Choosing the right materials is essential to ensure durability, cost-effectiveness, and, increasingly, product sustainability. How do we support this stage at JOM? Based on the part’s requirements, we recommend the ideal material: aluminum for lightweight components, stainless steel for greater durability, or iron for more cost-effective options. We also advise on surface treatments that can enhance durability, such as galvanization or powder coating.

4. Prototyping and Testing

Prototyping is essential for assessing the design’s functionality and quality before mass production. How do we proceed at JOM? We make as many prototypes as needed to validate the design while exploring improvements that optimize the product’s final cost. Each test brings us closer to the final product, ensuring it meets our clients’ quality standards.

5. Optimization of the Manufacturing Process

Industrial design also focuses on how the product will be manufactured, considering efficiency and production costs. And at JOM, how do we optimize this process? We offer a full range of manufacturing options, from stamping and manual pressing to laser cutting and engraving, as well as bending with specialized tools, adapting to the specific needs of each project.

6. Aesthetic Impact and Brand Identity

Beyond functionality, industrial design should express a visual identity that connects with the brand. At JOM, we consider ourselves inseparable partners of our clients, acting as an extension of their engineering and production teams. We understand their requirements and adapt our processes accordingly, fostering a relationship of trust and collaboration that allows us to work as if we were an integral part of their company.

Conclusion

At JOM METAL PARTS MANUFACTURING, S.L., we support our clients at every stage of industrial design, bringing our knowledge and experience to transform ideas into high-quality products that meet market demands. From needs analysis to production, we work to ensure the final result is an efficient, cost-effective product aligned with our clients’ values.