We are metal experts and are passionate about putting all the experience we have accumulated over the years at the service of our customers by offering them the best possible advice.

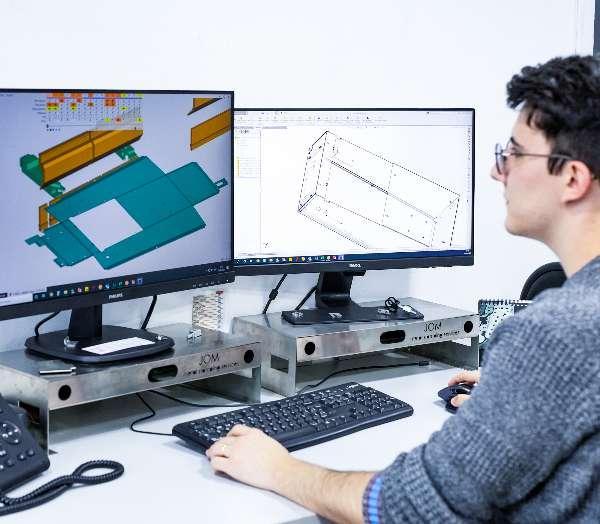

We industrialize the manufacture of any metal part, always defining the best production process. To do this, we combine all our manufacturing processes according to the needs of each project: die construction, metal stamping, laser cutting, punching, bending and welding, among others.

We work side by side with our customers to meet the objective in terms of costs and quality in each case. The interaction of our three manufacturing sections, tooling workshop, press section, and laser cutting, bending and welding, allows us to fully optimize the manufacture of any metal part or assembly.